Electric Braking of Dc Motor

Braking is usually employed

to stop or slow down the dc motor. Generally braking in dc machine is

classified as Electric Braking and Mechanical Braking. Generally,

electric braking is used to slow down the motor when motor goes slow down then

mechanical braking is applied to stop the motor at fixed position. Generally

electric braking is used in the application of dc motor where frequent or rapid

braking is required like train, hoist, metro train etc. The main principle of

electric braking is to apply negative torque as torque is directly proportional

to flux and armature current (T α ɸ.Ia) so torque can be

reversed by reversing the flux or armature current. Generally, Ia is

reversed. So when we apply electric braking then the motor tends to rotate in

opposite direction but we have to stop the motor so we have to apply mechanical

braking to stop the motor at final position.

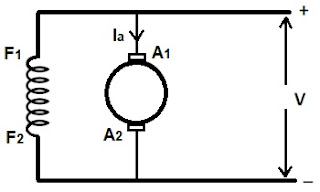

The above figure shown

represents the dc shunt machine working as motor. Now we will study the

different type of braking of motor referring to the above figure.

Types of Electric Braking in Dc Motor

There are three types of

braking of a dc motor these are

- Plugging

- Dynamic Braking

- Regenerative Braking

Plugging in Dc Motor

In this method armature terminals of motor (shunt motor or

separately excited motor) are reversed at the time

of braking. By reversing the armature terminals, the direction

of armature current is reversed. As the direction of armature current

is reversed then the direction of torque is also reversed (T α φ.Iₐ) this

reversed torque is known as braking torque. This braking torque will

reverse the direction of rotation and tends the motor to run in opposite

direction. In order to stop the motor at final position we need to apply

mechanical brakes. It is also known as Reverse

Current Braking.

In this method we did not change the direction of flux so direction of

supply voltage and induced voltage Eb (back emf) are same

therefore the voltage across the armature is V+Eb which is almost

twice the supply voltage.

The armature current is reversed

and a high braking torque is produced. In order to limit the armature current,

an external current limiting resistor is connected in series with the armature.

For braking of dc series motor

either the armature terminals or the field terminals are reversed.

Dynamic Braking of DC Motor

In dynamic braking, the

armature of dc motor is disconnected from supply and a braking resistor Rb is

immediately connected across the armature terminals and leaves the field

terminals connected to the supply. See if the field terminal is connected to

supply means flux(ɸ) is constant or in same direction and when the armature

terminals is disconnected from supply then armature is free to rotate in

constant flux and the dc motor work as dc generator and the direction of

armature current is reversed. As the direction of armature current is reversed

then the direction of torque is also reversed. Hence motor produces breaking

torque. It is also known as Rheostatic

Braking.

If breaking resistor is not

connected across the armature terminals, then the motor will take longer time

to stop. So for instant breaking, breaking resistor Rb is used.

For dynamic braking of dc

series motor, the field terminals of series motor is reversed and then the

motor is connected in series with braking resistor for instant braking.

Dynamic breaking is

inefficient method of braking, because all the energy is dissipate in

resistance.

Regenerative Breaking of dc Motor

It is the type of braking

in which kinetic energy of motor fed back to supply system. It is not an

intentional braking but it is an inherent property of motor i.e. when the motor

runs at a speed higher than its no load speed under constant excitation then

the motor back emf Eb is greater than the supply voltage, which

reverse the direction of armature current of motor. Then the dc machine

operates as dc generator and the energy generated is supply back to the source.

If the direction of armature current is reversed then the direction of torque

is also reversed and the machine produces braking torque.

Regenerative braking is

used where braking or slowing the motor is more frequent. It is most useful in

overhauling load. For example, when train is running at declined surface then

the speed of motor is greater than the no load speed of the motor and machine

produces the braking torque.

It wouldn’t stop the motor

but control the speed. It is used for controlling the speed above no load speed

of the motor.

No comments:

Post a Comment

Please feel free to provide feedback and suggestions, and also don't hesitate to ask your questions.