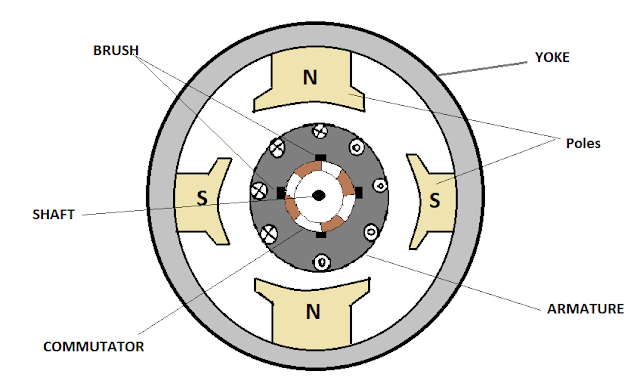

Dc Motor

Generally rotating machine contains

two parts the annular stationary part known as stator & the cylindrical rotatory

part is known as rotor, separated by a least possible air gap. The stator and

rotor are both made of ferromagnetic material (steel) which conducts the

magnetic flux upon which depends the process of energy conversion. Slots are

cut on the inner periphery of the stator and outer periphery of rotor

conductors are placed in the slots of stator and rotor. They are interconnected

to form winding. In dc machine field winding (concentrated type) is mounted on

stator and armature winding (distributed type) along with commutator is mounted

on rotor. The field poles are symmetrical and even in number, alternately north

and south.

There are several parts of Dc machine

Yoke

Poles

Armature core

Commutator

Brush

Bearings

Shaft

Yoke

The yoke of a dc machine is an

annular ring which provides the mechanical support for poles and it also

provides the path for flux. In small dc motor yoke made from fabricated steel

and in special application (power electronics converter) laminated steel is

used.

Poles

The main field flux is created by

poles excited with direct current. There are two types of poles permanent

magnet poles and electromagnet poles. Steel laminations are provided to reduces

pulsation losses i.e. eddy current loss.

Pulsation losses

Due to teeths and slots on the outer

periphery of rotor flux distribution is non uniform i.e. flux is pulsating with

high frequency which creates eddy currents (called pulsation losses) in the

pole shoes

Armature core

Armature is center for

electromechanical energy conversion hence it should have high permeability. The

armature is made up of silicon steel with slots cut out on the periphery to

accommodate the insulated armature winding. The ends of each armature coil are

connected to the commutator segments to form a closed winding. To reduce eddy

current losses thin laminations are provided. Laminations are cut parallel to

flux direction

Brush

Brush is used to collect current from

rotating commutator and winding. The brushes are alternatively positive and

negative (electrical angle between adjacent pair being 1800). These

are placed in brush Holder with the spring for good mechanical conditions. DC motor brushes are made up of copper, carbon, electro-graphite, cu-graphite.

In order to have successful

commutation the brushes are physically placed along d axis to short circuit the

coil along q axis but schematically brushes are shown at q axis/MNA.

Bearing

The function of the

bearings is to reduce friction between the rotating and stationary parts of the

machine. Bearings support the armature which is mounted on the shaft.

Shaft

The shaft is made of mild steel. The rotating parts like armature core and commutator are mounted and keyed to the shaft.

Commutator

Commutator is a mechanical switch which converts

alternating voltage and current which are induced in armature in Dc and it is

also called mechanical rectifier. The commutator is cylindrical in shape and

comprises several wedge shapped copper segments bound together while they are

insulated from each other.

Nice Bro

ReplyDelete